Manufacture

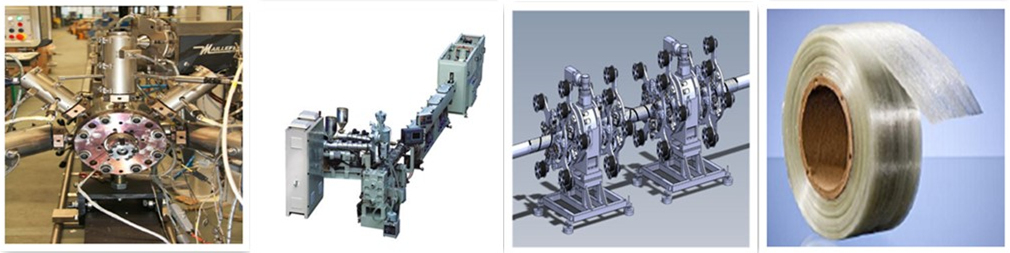

Your location is:Nachuan Fittings > ManufactureCurrently, the company owns a modern plant of total area over 20,000 square meters. In addition, Nacheon has introduced automatic production facilities including single layer extruding machine, multi-layer co-extruding machine, bi-directional winding machine, tractor and spooler, etc. Conservatively, the predicted production capacity is up to 100km per year.

With the sophisticated processing technologies, Nacheon would be able to produce full-fledged subsea flexible pipes with ID varying from 2 inch to 16 inch, working temperature ranging from -40 degree to 180 degree and fully applicable under 3000 meter water depth. During post-installation stage, we are committed to provide every customer meticulous commissioning service and cultivate a long-term win-win cooperative relationship.

One remarkable provement of Nacheon’s production ability is our patented three-layer co-extrusion PPS liner technique, which solves the compatible issue between different materials simultaneous extrusion. Based on the creative design of screw rod, hand piece and vacuum shaping and cooling technology, Nacheon is the only company who can achieve simultaneous three-layer extrusion PPS liner in China.