AFP concept

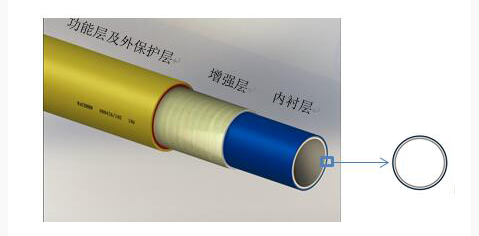

Your location is:Nachuan Fittings > AFP conceptAFP abbreviated for “All-Purpose Flexible Pipe”, can be applied in the extremely harsh environment such as ultra-deepwater or heavy oil exploitation.AFP shows unexceptional performance functioning as submarine risers, jumpers, downhole tubing and long-distance flowline, etc. The pipe system constructed from reinforced fibers and thermoplastic polymer is fully bonded with solid wall. With fibers embedded in the polymer matrix, this composite pipe can acquire strong interface adhesion between different layers. The pipe consists of an inner liner, thermoplastic composite reinforcement layers, a functional layer and an outer coating. All layers are of the same thermoplastic polymer and are welded together during the production process.

Inner liner: Single layer or three-layer co-extrusion solid wall; the selected materials for liner could be PP, PE, PA, PVDF, PPS, PEEK, etc. Reinforcement layer: Thermoplastic polymer reinforced with fully-bonded fibers processed by continuous winding; the polymer raw materials include PP, PE, PA, PVDF, PPS, PEEK, etc, and the fibers are classified as glass fiber, carbon fiber or aramid fiber, etc. Functional layer: Contained with electrical cable, optical fiber, various sensors or other function units, this layer plays an excellent role of data transmission, real-state monitoring and integrity control. Outer coating: Polymer extrusion; the suitable polymer materials such as PP, PE, PA, PVDF, PPS and PEEK are adopted to produce outer coating. No corrosion Flexible and spoolable Light-weight, reduction of top-tension requirement and transportation cost High pressure rating Excellent fatigue resistance Longer service life Smooth bore – less wax deposition, less pressure loss, less internal flow-induced vibration Lower U-value compared to steel pipe Lower requirement for installation vessel Lower cost for installation and operation The product overview Internal Diameter 2~16 inch Maximum Water Depth 3000 m Service Life 30 years Operating Temperature -40 ℃ to 180 ℃ Loading Capacity Maximum internal pressure rating 60MPa, maximum external pressure rating 30MPa Corrosion Resistance The inner liner of thermoplastic polymer can decrease corrosion rate of MIC, SRB, H2S, CO2 and other chemical reagent. Fatigue Resistance Due to the great flexibility, the bend radius is smaller, the fatigue resistance is great Fluid Compatibility Water, oil and gas, single phase or multiphase fluids Thermal Conductivity Low U-value compared to steel pipe Light Weight 40% lighter than the traditional metal structure flexible pipe, no additional floating buoy is required Easy to Installation Convenient, cost-effective installation